INternet of Things

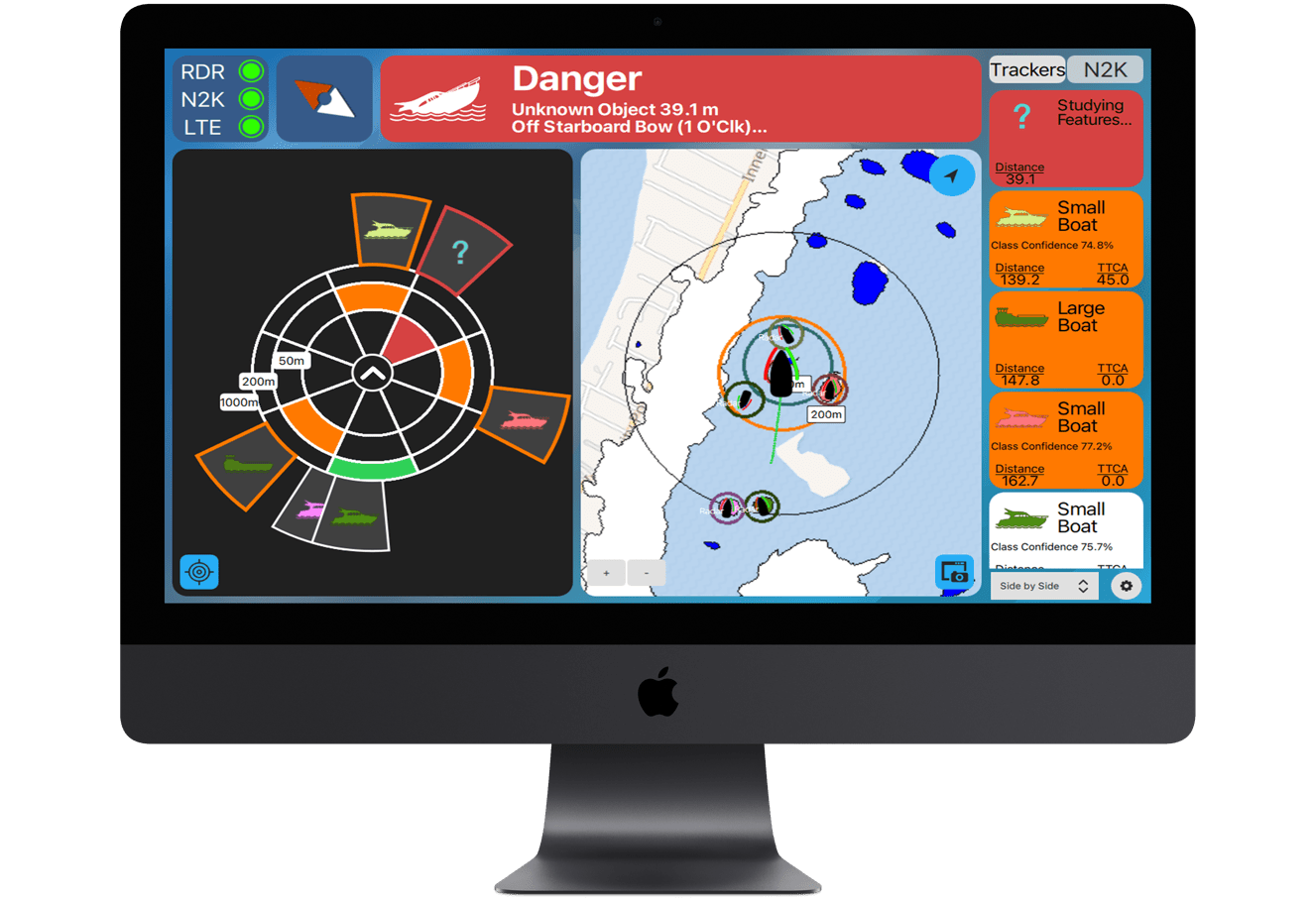

Machine Learning

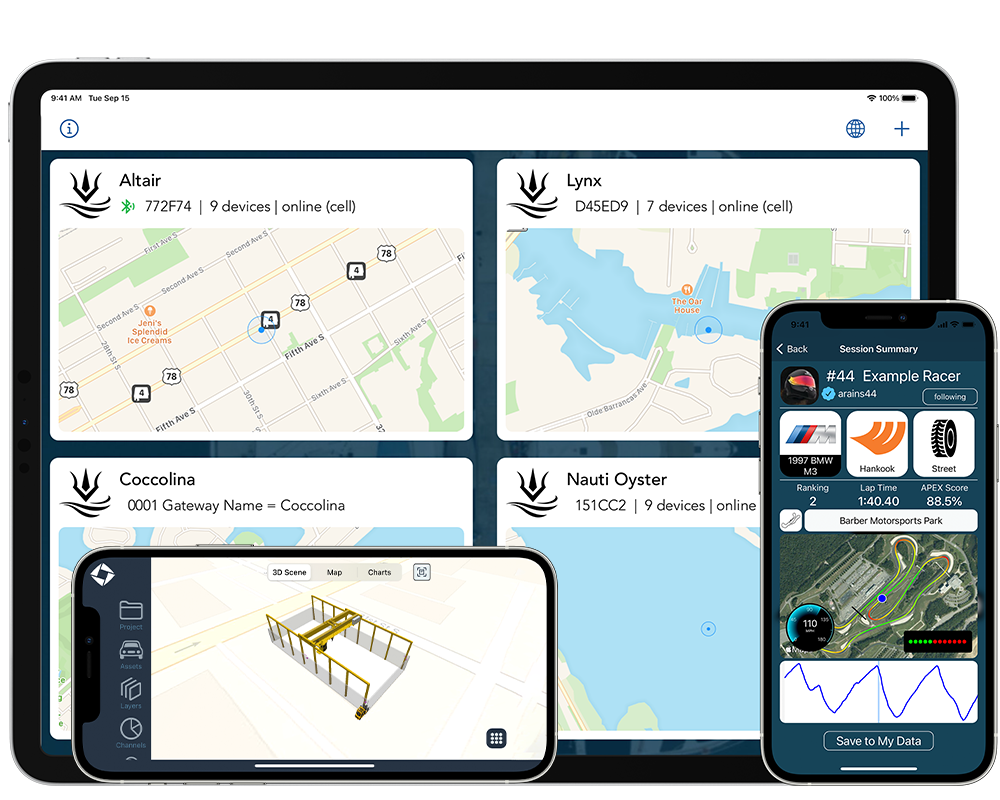

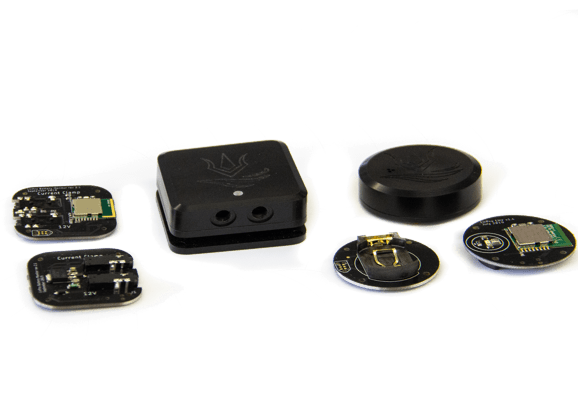

The world is connected like never before - lights, coffee makers, washing machines, cars - all connected and accessible over your local network. Deft has the skill, knowledge, and experience to take your product to the next level by connecting it to the internet of things via Wi-Fi and secure Bluetooth 5 mesh. Remote control, information streaming, data analysis, machine learning: all from the your smartphone or computer.

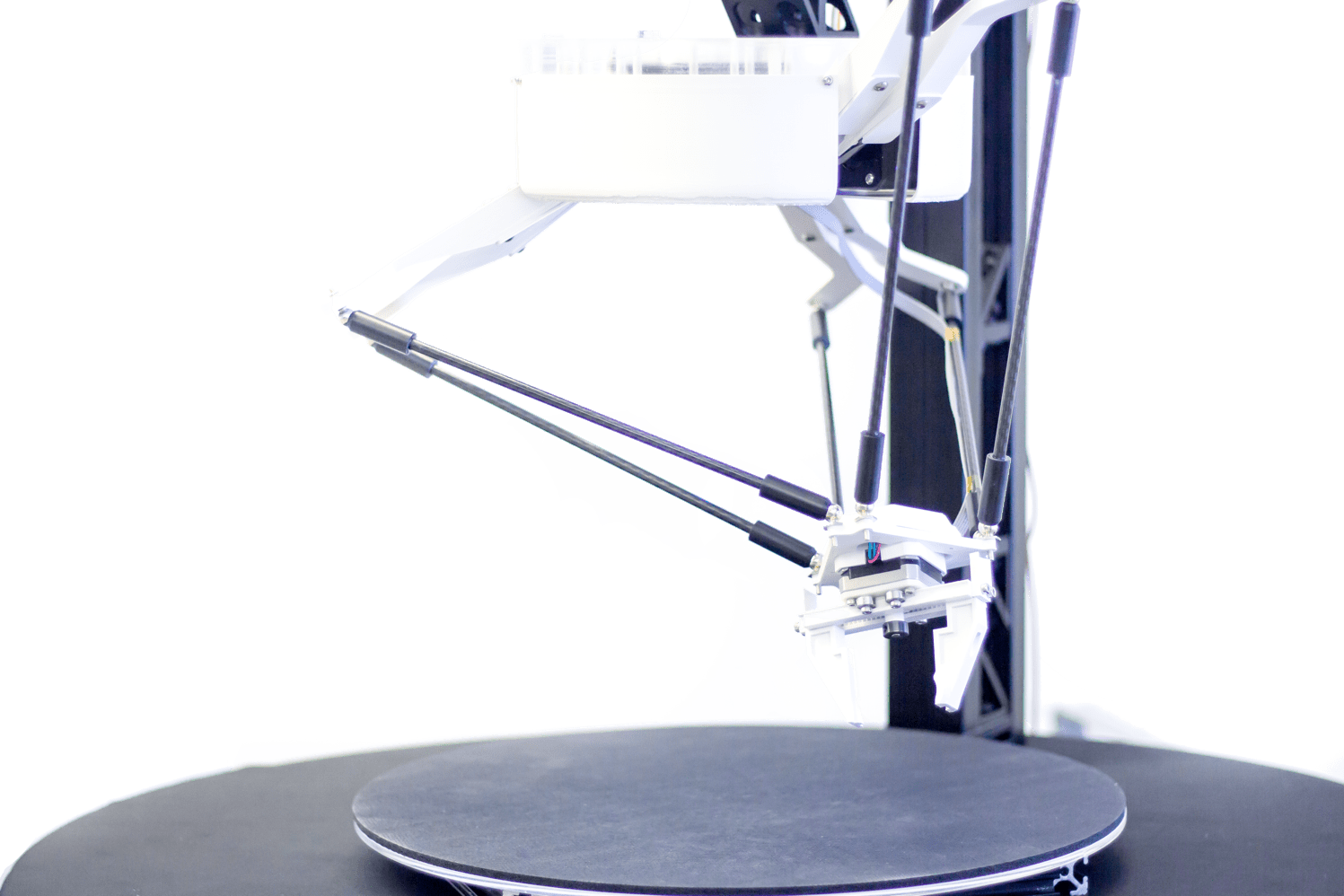

Successful and meaningful products requires constant innovation. Deft utilizes industry standard and cutting edge technology in our production process and technology development.

Connecting advanced machinery and electronics to software for data gathering and machine learning can be challenging. Since our inception, Deft has been perfecting combining software and hardware to create products that are relevant and distinct.

Questions? want to learn more about how we can help your project?

Contact Us